As a product editor, I understand the importance of a well-functioning livewell pump and baitwell pumps in maintaining the vitality of aquatic life. Livewell pumps play a crucial role in providing a continuous flow of oxygenated water, ensuring the well-being of bait and fish in your boat or fishing vessel.

Efficient Livewell Pump Systems

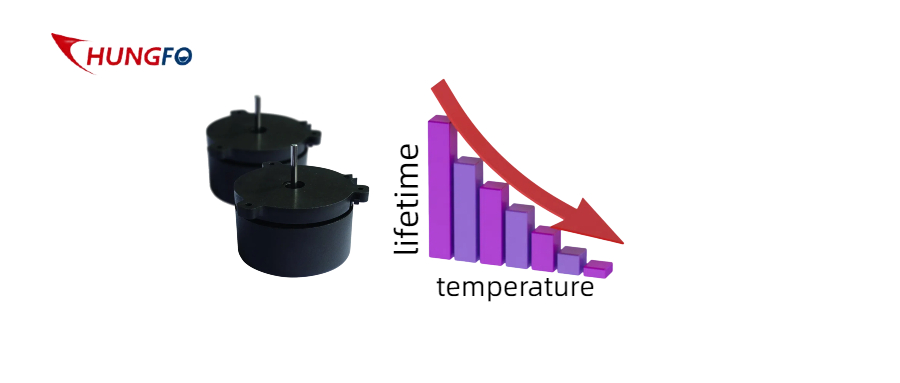

Livewell pumps are designed to circulate water throughout the livewell or baitwell, keeping it fresh and aerated. This is vital for maintaining the health of live bait and sustaining fish in catch-and-release situations. These pumps are reliable and built to withstand the robust demands of marine environments, ensuring longevity and high performance.

Benefits of Quality Livewell Pumps

Optimal Water Circulation: Livewell pumps provide a steady flow of fresh water, preventing stagnation and maintaining oxygen levels for active bait and fish.

Adjustable Flow Rates: Many livewell pumps offer adjustable flow rates, allowing you to regulate water flow based on the size and quantity of the aquatic life you carry.

Quiet Operation: Modern livewell pumps are engineered to operate silently, reducing noise disruptions and ensuring a tranquil onboard experience.

Energy Efficiency: Livewell pumps have become increasingly energy-efficient, minimizing power consumption while maintaining effective water circulation.

Easy Installation and Maintenance: Livewell pumps are designed for ease of installation and maintenance, ensuring hassle-free usage and minimal downtime.

Selecting the Right Livewell Pump

When choosing a livewell pump for your boat or fishing vessel, consider the following factors:

Flow Rate: Ensure the pump’s flow rate meets the requirements of your baitwell or livewell size.

Durability and Quality: Look for pumps made of corrosion-resistant materials, as they will endure the harsh marine environment and withstand long-term use.

Power Efficiency: Energy-efficient pumps minimize power consumption, preserving battery life during extended fishing trips.

Additional Features: Some pumps come with built-in automatic switch systems, ensuring water circulation without manual intervention.

Noise Level: Opt for models that operate quietly to provide a serene environment onboard.

Maintaining your Livewell Pump

To prolong the lifespan of your livewell pump, adhere to these maintenance practices:

Regular Cleaning: Clean the pump, strainer, and plumbing system to remove any debris or blockages that may impede the pump’s performance.

Inspect for Wear and Tear: Routinely inspect the pump for signs of wear or damage, such as frayed wires or cracked housing. Replace any faulty components promptly.

Winterizing: Before freezing temperatures arrive, ensure your livewell pump is properly winterized by draining all water and protecting it from potential freezing.

By selecting a quality livewell pump and maintaining it meticulously, you’ll ensure the smooth operation of your baitwell system, guaranteeing optimal conditions for your bait and fish. Invest in a reliable livewell pump and prioritize the welfare of aquatic life during your fishing adventures.